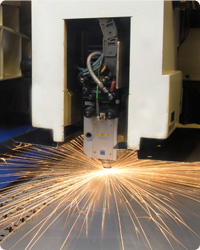

Laser Cutting

|

S&D Products has expanded its commitment to production of the highest quality part by the introduction of the latest laser cutting technology. Our CNC laser cutting capabilites are based on our years of metal working experience coupled with the very finest CNC laser cutting equipment and our trained staff. S&D Products CNC Laser Cutting capabilities provide for quick turnaround times and rapid production of complex items that require precise dimensions, shapes and cuts.

|

Vital Information for Laser Cutting

|

Automation |

Operators trained & certified in the use of multiple machines. | |

| Metal Forming Capabilities |

• CNC Punching • CNC Laser Cutting • CNC Stamping |

• Press Brake Forming • Punch Press Stamping • Metal Stamping

|

|

Secondary Operations |

• Tooling • Die Tapping • Tapping & Deburring • Staking • Cleaning |

• Heat Treating • Plating • Anodizing • Painting • Value Added Processes |

| Materials |

• Aluminum (various grades) • Mild Steel • High Strength (HSLA) Steel • Cold Rolled Steel • Hot Rolled Pickled & Oiled Steel (HRP&O) • Galvanized Steel |

• Brass • Copper • Stainless Steel (various grades) • Titanium • Other Materials, Gages, Thickness & Tolerances |

|

Volume Capabilities |

Prototype Runs to Several Million Pieces Annually Depending on Product Complexity & Application | |

| Material Size and Laser Cutting Capacity | Laser Cutting up to 3/4" (.75 inch) steel, 1/2" (.5 inch) stainless steel, 3/8" (.375 inch) aluminum with a maximum sheet size of 5" x 10". | |

|

Quality Assurance |

• KAN BAN/LEAN • JIT • Six Sigma Capabilities • EDI Electronic Data Interchange • C of C Certificate of Compliance • PPAP • Conform to ISO 9001 best practices |

|

| Data Exchange |

• ProEngineer • AutoCAD • Master CAM • SolidWorks Part Files • Catia CAD/CAM |

• SolidWorks Assembly Files • 2D & 3D DXF Files • 2D & 3D IGES Wireframe • Other CAD/CAM Formats • PDF, JPEG |

| Industries Served |

• Agriculture Equipment • Air Conditioning Equipment • Audio Distribution Components • Automation Equipment • Automotive (tier 2 or 3) • Bath & Shower • Boat Builders • Boating • Cabinets • Components Automation Equipment • Computer Equipment • Controls & Instrumentation • Department of Defense • Electronics & Control Cabinets • Food Processing Equipment • Government • Hardware Distributors • Heating, Ventilation & AC Equipment |

• Home Hardware • Marine Hinges • Manufacturing Equipment • Medical Devices • Medical Appliances • Military & Defense • OEM Products • Power Systems • Recreational Vehicles • Restaurant Equipment • Security Equipment • Subsystem Enclosures • Storm Doors • Specialty Use Vehicles • Toolboxes • Transportation • Truck Body |

| Hinges |

• Continuous Hinges • Piano Hinges • Heavy Duty Hinges • Custom Hinges • More Hinges |

|

Laser Cutting Defined

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high-powered laser. The material then either melts, burns, vaporizes away, or is blown away by a jet of gas leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

|

Generation of the laser beam involves stimulating a lasing material by electrical discharges or lamps within a closed container. As the lasing material is stimulated, the beam is reflected internally by means of a partial mirror, until it achieves sufficient energy to escape as a stream of monochromatic coherent light. Mirrors or fiber optics are typically used to direct the coherent light to a lens, which focuses the light at the work zone.

The narrowest part of the focused beam is generally less than 0.0125 in (0.3175 mm). in diameter. Depending upon material thickness, kerf widths as small as 0.004 in (0.1016 mm) are possible.[4] In order to be able to start cutting from somewhere else than the edge, a pierce is done before every cut. Piercing usually involves a high-power pulsed laser beam which slowly (taking around 5–15 seconds for 1⁄2-inch-thick (13 mm) stainless steel, for example) makes a hole in the material. There are many different methods in cutting using lasers, with different types used to cut different material. Some of the methods are vaporization, melt and blow, melt blow and burn, thermal stress cracking, scribing, cold cutting and burning stabilized laser cutting. |

S&D Producs, INC.1390 Schiferl Road

Bartlett, IL 60103 |